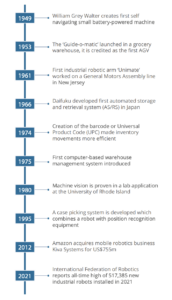

Warehouse technology has come a long way from conveyor belts and workers pushing trolleys…

Demand on space and labour has led to warehouses across the UK turning to automation, robotics and artificial intelligence (AI) to become as efficient, and as safe, as possible. When looking at the type of technology installed in these warehouses, there is a differentiation between those used to replenish bricks-and-mortar stores and those sites purely for ecommerce fulfilment.

For more traditional retail warehouse models, automation is used to handle large bulky cases and pallets. Whereas, for direct-to-customer orders the technology needs to be able to handle individual items. This means it has to be flexible, agile and in some cases able to make decisions in real-time.

Warehouse technology can be hand-held, wearable or even require no human intervention at all. Whether Automated Guided Vehicles (AGVs), which follow predefined paths, or Autonomous Mobile Robots (AMRs), that can understand and move through environments without being overseen directly by an operator, warehouses are deploying robots for a series of labour intensive tasks. This is especially true in ecommerce, which requires a high degree of flexibility.

Furthermore, collaborative robots (cobots) are also being installed to take the strain of picking and packing operations. Rueben Scriven, warehouse automation analyst, explains to best understand the adoption of robotics in ecommerce warehousing simply think about it in terms of the workflows. There is receiving, storage, buffering, picking, and then staging and loading.

“Each of those different workflows has a myriad of different types of technologies being used, either fixed or mobile automation,” Scriven notes. For omnichannel operations mobile automation is particularly important due to the need for agility. While earlier fixed automated systems did not possess any flexibility, the advancing mobile solutions provide the opportunity to scale up with changing demands.

Robot vs Human

Providing ecommerce warehouses with adaptability is one clear benefit of deploying robotic technology. These technologies also have the potential to take on strenuous, repetitive tasks from warehouse workers. Industry experts will stress that any fear of robots taking human jobs should be quashed. Scriven states: “robotics has never led to someone getting fired.”

He continues: “Robotics are really used to add additional value and allow people to do alternative work, which provides more value to the company. It’s not that there’s a fixed amount of work that they have to do, and if they bring in robots it means less labour. It means that if they bring in automation they can use their existing labour to generate better and more efficient operations.”

Interact Analysis has mapped the labour spend per warehouse with the automation spend per warehouse. It found an “almost perfect linear line” where as labour spend per warehouse goes up, automation spend per warehouse also increased in a corresponding manner. Furthermore, it found that the UK has the highest automation spend per warehouse out of any country in the world.

Artificial intelligence

Before rolling out the robots to work alongside human operatives, companies will also require the right software to do so. And this is also becoming more advanced. Warehouse management software, which once used a simple algorithm, can now harness the power of AI for increased responsiveness. AI can take into account a number of different variables. It can automate decision making and provides “dynamic intelligence”.

And similarly to its hardware companions, AI is incredibly good at “doing very monotonous tasks over and over again, and identifying patterns,” Scriven explains. It can go through vast amounts of data and flag things, which enables businesses to make informed decisions.

Renting robots

The benefits of adopting AI and robotics in an ecommerce warehouse may be becoming increasingly clear to companies, but they also come with a large price tag. Some may question whether the initial large investment will be worth it. There are new business models that may open doors for companies wishing to access automation without the down payment, including Robotics-as-a-Service (RaaS). AMR and cobot providers are leasing their solutions to businesses, with the opportunity to scale up or down when needed.

On-demand automation can also come in the form of cloud-based subscription services for AI software. Such RaaS offerings have the power to “democratisation automation” , notes Scriven, with medium-sized businesses able to benefit from robotics without the often cost-prohibitive investment.

This feature originally appeared in the DeliveryX Warehousing 2023 Report, download it in full here.